FabCon is coming to Atlanta

Join us at FabCon Atlanta from March 16 - 20, 2026, for the ultimate Fabric, Power BI, AI and SQL community-led event. Save $200 with code FABCOMM.

Register now!- Power BI forums

- Get Help with Power BI

- Desktop

- Service

- Report Server

- Power Query

- Mobile Apps

- Developer

- DAX Commands and Tips

- Custom Visuals Development Discussion

- Health and Life Sciences

- Power BI Spanish forums

- Translated Spanish Desktop

- Training and Consulting

- Instructor Led Training

- Dashboard in a Day for Women, by Women

- Galleries

- Data Stories Gallery

- Themes Gallery

- Contests Gallery

- QuickViz Gallery

- Quick Measures Gallery

- Visual Calculations Gallery

- Notebook Gallery

- Translytical Task Flow Gallery

- TMDL Gallery

- R Script Showcase

- Webinars and Video Gallery

- Ideas

- Custom Visuals Ideas (read-only)

- Issues

- Issues

- Events

- Upcoming Events

The Power BI Data Visualization World Championships is back! Get ahead of the game and start preparing now! Learn more

- Power BI forums

- Forums

- Get Help with Power BI

- Desktop

- Re: Sum up columns based on date

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Sum up columns based on date

I have 3 tables of data below. "Current Inventory", "Open requisition orders" to resupply inventory, and "Production Schedule Demand". I am wanting to calculate at what point we will run out of inventory based on the current information.

| Current Inventory | |

| Part # | Unrestricted stock |

| Motor | 1 |

| Alternator | 0 |

| Pulley | 5 |

| Panel | 16 |

| Open requisition orders | ||

| Part # | Delivery date | Quantity |

| Motor | 6/22/2022 | 5 |

| Alternator | 7/21/2022 | 3 |

| Pulley | 7/21/2022 | 10 |

| Panel | 7/21/2022 | 1 |

| Motor | 8/24/2022 | 5 |

| Pulley | 9/1/2022 | 10 |

| Panel | 9/1/2022 | 5 |

| Production Schedule demand | |||||

| Part # | Job # | Required Quantity | Required date | ||

| Motor | 12345 | 1 | 7/1/2022 | ||

| Alternator | 12345 | 2 | 7/1/2022 | ||

| Pulley | 12345 | 6 | 7/1/2022 | ||

| Panel | 12345 | 2 | 7/1/2022 | ||

| Motor | 67890 | 3 | 7/30/2022 | ||

| Alternator | 67890 | 6 | 7/30/2022 | ||

| Pulley | 67890 | 6 | 7/30/2022 | ||

| Panel | 67890 | 2 | 7/30/2022 | ||

| Motor | 98765 | 3 | 7/31/2022 | ||

| Alternator | 98765 | 6 | 7/31/2022 | ||

| Pulley | 98765 | 6 | 7/31/2022 | ||

| Panel | 98765 | 2 | 7/31/2022 | ||

| Motor | 43210 | 1 | 9/1/2022 | ||

| Alternator | 43210 | 2 | 9/1/2022 | ||

| Pulley | 43210 | 6 | 9/1/2022 | ||

| Panel | 43210 | 2 | 9/1/2022 |

Solved! Go to Solution.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

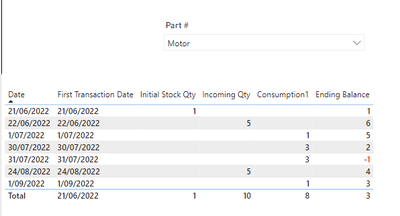

Hi @bstrak1287

Refer to below as the value displayed -13 for alternator.

Logic used

current inventory (add a date column which can be 1 day less (Minimum value) than your purchase order/sales order).

Make one table with all data included as below.

current inv - Inital stock.

purchase order - Incoming qty

Work/sales order - consumption.

Create a data table 1 day earlier (as initial stock) and last date as maximum of (work order / purchase order).

You can download the file from below and work around.

https://drive.google.com/file/d/1Bl5qSBtGrnHRhEgN9Sn1kfgQp1gHHFuV/view?usp=sharing

Refer to Enterprise DNA, SQLBI for Inventory dashboard.

Let me if this solution is accepted.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi bstark,

I think required qty is missing production schedule.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

@indkitty apologies it was there, it was just formatted in a way it was tough for me to even discern. I have added columns in between other values to make it easier to read. Thank you for letting me know!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

@bstark1287 Not a problem. Have you built Power BI Dashboard (i.e Pbix) file. If yes, can you share through Google drive/One Drive?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

I am sorry but I am unable to share due to security settings. I tried just copying and pasting into a dummy powerbi file to attach here but I am not able.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

You cannot add here. Share it with Google Drive/One Drive.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

@indkitty I was able to upload it here to my onedrive https://1drv.ms/u/s!ApMyUgRWG_6Cjjd7xDi_TJEZgMSF?e=NZPNbb

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi bstark,

I have built using the data posted.

for motor stock runouts on 31/07/2022 (partial competion of orders).

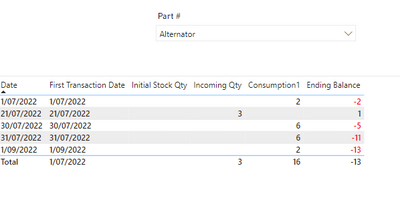

for alternator

starting inventory itself is 0, it can only run on 21/07/2022 with remaining qty. then following orders are blank.

Let me know if this is what you wanted.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

@indkitty This is really close to what I am looking for! Can you share how you got these results? Basically I would like to have a slicer for the date so if I select say 7/31/22, it would show I have a negative quantity of 5 alternators which will affect job # 67890. Then if I change my slicer to 9/1/22 it would show alternators with a negative quantity of 13. I think if you share how you got this far I could possibly take it the rest of the way. What you have so far is awesome!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi @bstrak1287

Refer to below as the value displayed -13 for alternator.

Logic used

current inventory (add a date column which can be 1 day less (Minimum value) than your purchase order/sales order).

Make one table with all data included as below.

current inv - Inital stock.

purchase order - Incoming qty

Work/sales order - consumption.

Create a data table 1 day earlier (as initial stock) and last date as maximum of (work order / purchase order).

You can download the file from below and work around.

https://drive.google.com/file/d/1Bl5qSBtGrnHRhEgN9Sn1kfgQp1gHHFuV/view?usp=sharing

Refer to Enterprise DNA, SQLBI for Inventory dashboard.

Let me if this solution is accepted.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi, @bstark1287

Can you share your expected results for further research?

Best Regards,

Community Support Team _ Eason

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

@v-easonf-msft I would like something very similar to the attached below. I have a slicer for the date which affects a custom measure (unrestricted stock - production schedule demand + open requisition orders). I would like to add a drill through to the part # that would show the production orders creating the cumulative total.

Helpful resources

Power BI Dataviz World Championships

The Power BI Data Visualization World Championships is back! Get ahead of the game and start preparing now!

| User | Count |

|---|---|

| 38 | |

| 36 | |

| 33 | |

| 33 | |

| 29 |

| User | Count |

|---|---|

| 134 | |

| 96 | |

| 78 | |

| 67 | |

| 65 |