FabCon is coming to Atlanta

Join us at FabCon Atlanta from March 16 - 20, 2026, for the ultimate Fabric, Power BI, AI and SQL community-led event. Save $200 with code FABCOMM.

Register now!- Power BI forums

- Get Help with Power BI

- Desktop

- Service

- Report Server

- Power Query

- Mobile Apps

- Developer

- DAX Commands and Tips

- Custom Visuals Development Discussion

- Health and Life Sciences

- Power BI Spanish forums

- Translated Spanish Desktop

- Training and Consulting

- Instructor Led Training

- Dashboard in a Day for Women, by Women

- Galleries

- Data Stories Gallery

- Themes Gallery

- Contests Gallery

- QuickViz Gallery

- Quick Measures Gallery

- Visual Calculations Gallery

- Notebook Gallery

- Translytical Task Flow Gallery

- TMDL Gallery

- R Script Showcase

- Webinars and Video Gallery

- Ideas

- Custom Visuals Ideas (read-only)

- Issues

- Issues

- Events

- Upcoming Events

The Power BI Data Visualization World Championships is back! Get ahead of the game and start preparing now! Learn more

- Power BI forums

- Forums

- Get Help with Power BI

- Power Query

- Need assistance creating a consumption/replenishme...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Need assistance creating a consumption/replenishment report.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

That's a tall project for starting with Power BI. In addition to that you need to know that Power BI has no memory. It cannot do any manipulations on existing datasets. It always reloads everything. That means you need to do the logging and history keeping outside of Power BI.

In addition, some of your tables are in a format that Power BI does not like (especially Consumption breakout). You would have to unpivot them and bring them into usable shape before attempting any logic implementation. However they don't seem to be required so I didn't load them.

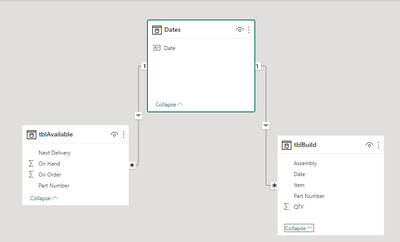

Here's the data model I would propose:

Did you know you have quite a few "Next Delivery Date" values in the past?

Anyway - next you would do the material planning to see how far you can stretch the parts. Are you assuming that item 1 has higher priority than item 2 etc ? If not then you would need to specify the priority somewhere.

Frankly speaking - Power BI is a reporting tool. It is not the right tool for material allocation, production planning and inventory management. That's what ERP systems are for.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Thanks for the reply. This is just a facsimile data set of what I'm actually working with, so dates aren't representative of real dates. The consumption breakout was a resulting table, not an input.

The real thing I'm looking to see if I can do is get a running subtractive total column added to the Consumption Schedule but I can't figure out how to a) set the initial value from tblAvailable then b) subtract the values in the Consumption Schedule from it. I've added an index column in my working file.

ex: part001: would start at 18 from tblAvailable, subtract 5 and return 13, subtract 5 and return 8, subtract 5 and return 3, subtract 5 and return -2, subtract 5 and return -7, etc. based on the way it is ordered on the consumption schedule.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

my previous opinion still stands: Power BI is a reporting tool. It is not the right tool for material allocation, production planning and inventory management. That's what ERP systems are for.

Helpful resources

Power BI Dataviz World Championships

The Power BI Data Visualization World Championships is back! Get ahead of the game and start preparing now!

| User | Count |

|---|---|

| 19 | |

| 9 | |

| 8 | |

| 7 | |

| 6 |