- Power BI forums

- Updates

- News & Announcements

- Get Help with Power BI

- Desktop

- Service

- Report Server

- Power Query

- Mobile Apps

- Developer

- DAX Commands and Tips

- Custom Visuals Development Discussion

- Health and Life Sciences

- Power BI Spanish forums

- Translated Spanish Desktop

- Power Platform Integration - Better Together!

- Power Platform Integrations (Read-only)

- Power Platform and Dynamics 365 Integrations (Read-only)

- Training and Consulting

- Instructor Led Training

- Dashboard in a Day for Women, by Women

- Galleries

- Community Connections & How-To Videos

- COVID-19 Data Stories Gallery

- Themes Gallery

- Data Stories Gallery

- R Script Showcase

- Webinars and Video Gallery

- Quick Measures Gallery

- 2021 MSBizAppsSummit Gallery

- 2020 MSBizAppsSummit Gallery

- 2019 MSBizAppsSummit Gallery

- Events

- Ideas

- Custom Visuals Ideas

- Issues

- Issues

- Events

- Upcoming Events

- Community Blog

- Power BI Community Blog

- Custom Visuals Community Blog

- Community Support

- Community Accounts & Registration

- Using the Community

- Community Feedback

Register now to learn Fabric in free live sessions led by the best Microsoft experts. From Apr 16 to May 9, in English and Spanish.

- Power BI forums

- Forums

- Get Help with Power BI

- Desktop

- Re: Cumulative inventory Forecast

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Cumulative inventory Forecast

Good Morning Everyone!

I am new to power bi and i got stuck on inventory forecasting.

I am having problems forecasting the inventory value remaining by code on a weekly basis.

I have a table stating the On hand value and another table showing the forecast consuming the inventory every week.

I want to create a leading indicator graph which will allow me to start from the on hand inventory level and remove or add forecast each week.

The idea here is to then imput Safety stock levels or Upper and Lower Control Limits to each code so that we can quickly tell which products we will have problems on.

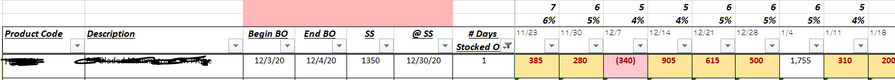

Here are pictures of what i would like as a final stage:

ex 385 is the initial inventory, then next week the forecast is netting out 105 units so i will only have 280 on hand and so on and so forth.

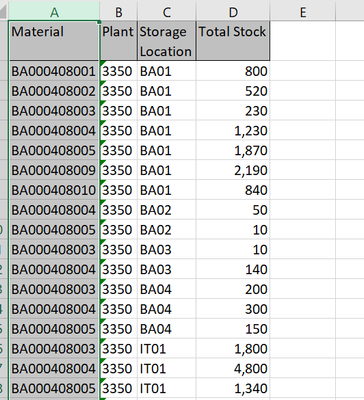

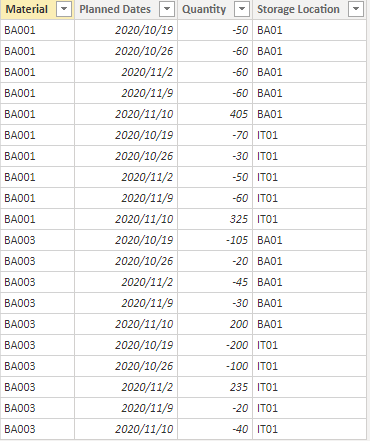

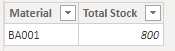

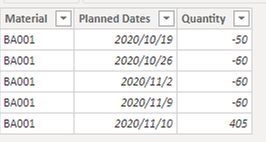

Here are 2 pictures of the databases that i am trying to extrapolate this info from: Forecast, and On Hand.

Forecast

On Hand

Ideally i would love to run these 2 reports daily and see what products will go negative or below safety stock in a quickly manner.

**Products and quantities are made up for this exercise**

Thank you again for your help with this !

Solved! Go to Solution.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi @andreaspa

I update my tables and my measure.

Forecast Table:

On Hand Table:

Safety Stock Table:

Measures:

Stock =

VAR _CHANGE =

SUMX (

FILTER (

ALL ( Forecast ),

Forecast[Planned Dates] <= MAX ( Forecast[Planned Dates] )

&& Forecast[Material] = MAX ( Forecast[Material] )

&& Forecast[Storage Location] = MAX ( Forecast[Storage Location] )

),

Forecast[Quantity]

)

VAR _Total =

SUMX (

FILTER (

'On Hand',

'On Hand'[Material] = MAX ( Forecast[Material] )

&& 'On Hand'[Storage Location] = MAX ( 'Forecast'[Storage Location] )

),

'On Hand'[Total Stock]

)

RETURN

_CHANGE + _TotalColor =

IF (

[Stock]

>= CALCULATE (

MAX ( 'Safety stock'[SafeQT] ),

FILTER (

'Safety stock',

'Safety stock'[Material] = MAX ( Forecast[Material] )

&& 'Safety stock'[Storage Location] = MAX ( 'Forecast'[Storage Location] )

)

),

1,

0

)

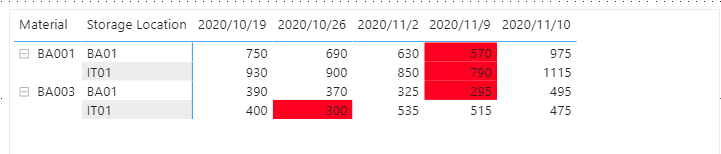

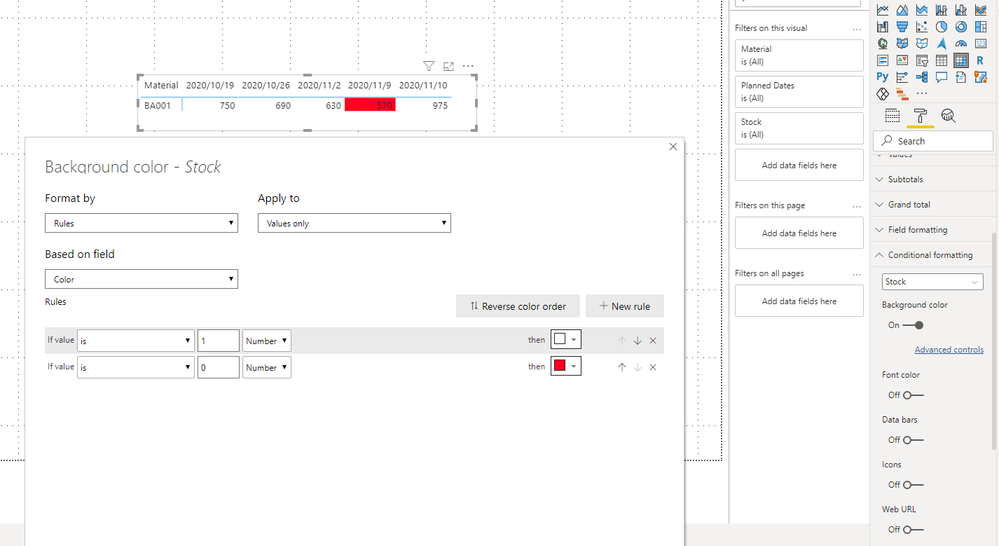

Result:

If this reply still couldn't help you solve your problem please show me more details about your tables.

Here I have some question:

1. In your On Hand Table: Storage Location for BA000408001 is BA01. However in your Forecast Table, Storage Location is Blank when reqd quantity <0, and Storage Location is IT01 when reqd quantity>0. I couldn't find BA01 in your Forecast Table.

2. Does each material have the same planned dates like my sample?

You can download the pbix file from this link: Cumulative inventory Forecast

Best Regards,

Rico Zhou

If this post helps, then please consider Accept it as the solution to help the other members find it more quickly.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

@v-rzhou-msft Thank you for your help !

I am now able to calculate what i needed.

The graphing part is very slow but i will try to fix this in other ways.

Thanks again!

Andrea

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi @andreaspa

I think you want to accumulate forecast on Total stock by each date.

I build two sample table to have a test.

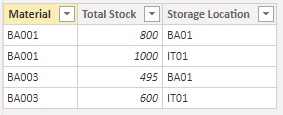

On Hand Table:

Forecast Table:

Measure:

Stock =

VAR _CHANGE = SUMX(FILTER(ALL(Forecast),Forecast[Planned Dates]<=MAX(Forecast[Planned Dates])&&Forecast[Material]=MAX(Forecast[Material])),Forecast[Quantity])

VAR _Total = SUMX(FILTER('On Hand','On Hand'[Material]=MAX(Forecast[Material])),'On Hand'[Total Stock])

Return

_CHANGE+_Total

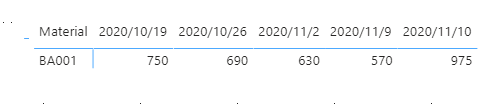

Matrix:

And you can flag the cell in other color if the stock less than safety stock by conditional formmatting.

I build a target table.

Color measure:

Color = IF([Stock]>= CALCULATE(MAX('Safety stock'[SafeQT]),FILTER('Safety stock','Safety stock'[Material]=MAX(Forecast[Material]))),1,0)

Result:

You can download the pbix file from this link: Cumulative inventory Forecast

Best Regards,

Rico Zhou

If this post helps, then please consider Accept it as the solution to help the other members find it more quickly.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi @v-rzhou-msft ,

First of all i want to thank you for your help with this!

your answer is very helpful but i don't think it solves the problem in full.

The dataset i sent you has different storage locations which i will need to be able to filter from in the measure you provided me with called " Stock" .

Also the dataset has multiple products so the 1 to many relationships that you provided me with for the connections between on Hand table and Forecast table won't work on this.

Let me know if you know how to fix this,

either way thank you so much for your super helpful tips!

Best,

Andrea

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi @andreaspa

I update my tables and my measure.

Forecast Table:

On Hand Table:

Safety Stock Table:

Measures:

Stock =

VAR _CHANGE =

SUMX (

FILTER (

ALL ( Forecast ),

Forecast[Planned Dates] <= MAX ( Forecast[Planned Dates] )

&& Forecast[Material] = MAX ( Forecast[Material] )

&& Forecast[Storage Location] = MAX ( Forecast[Storage Location] )

),

Forecast[Quantity]

)

VAR _Total =

SUMX (

FILTER (

'On Hand',

'On Hand'[Material] = MAX ( Forecast[Material] )

&& 'On Hand'[Storage Location] = MAX ( 'Forecast'[Storage Location] )

),

'On Hand'[Total Stock]

)

RETURN

_CHANGE + _TotalColor =

IF (

[Stock]

>= CALCULATE (

MAX ( 'Safety stock'[SafeQT] ),

FILTER (

'Safety stock',

'Safety stock'[Material] = MAX ( Forecast[Material] )

&& 'Safety stock'[Storage Location] = MAX ( 'Forecast'[Storage Location] )

)

),

1,

0

)

Result:

If this reply still couldn't help you solve your problem please show me more details about your tables.

Here I have some question:

1. In your On Hand Table: Storage Location for BA000408001 is BA01. However in your Forecast Table, Storage Location is Blank when reqd quantity <0, and Storage Location is IT01 when reqd quantity>0. I couldn't find BA01 in your Forecast Table.

2. Does each material have the same planned dates like my sample?

You can download the pbix file from this link: Cumulative inventory Forecast

Best Regards,

Rico Zhou

If this post helps, then please consider Accept it as the solution to help the other members find it more quickly.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

@v-rzhou-msft I am having the same problem as the OP, however my planned dates are all different. They aren't the same for each type of material. How can I alter the "Stock" measure to account for this?

Helpful resources

Microsoft Fabric Learn Together

Covering the world! 9:00-10:30 AM Sydney, 4:00-5:30 PM CET (Paris/Berlin), 7:00-8:30 PM Mexico City

Power BI Monthly Update - April 2024

Check out the April 2024 Power BI update to learn about new features.

| User | Count |

|---|---|

| 110 | |

| 94 | |

| 82 | |

| 66 | |

| 58 |

| User | Count |

|---|---|

| 151 | |

| 121 | |

| 104 | |

| 87 | |

| 67 |